Our Series 5 Embedded OS is at the heart of all our systems. We build on 8 years of in-market experience developing TEC controllers. Series 5 provides a stable, fault tolerant platform for solving difficult temperature control problems. The field proven BMP PID Engine is at the heart of the OS.

Networked operation has been designed into Series 5 from the beginning. Controllers can be individually addressed, or addressed in groups. Both digital load balancing and automatic failover to a hot standby are supported.

A full web based interface is provided. Brand new user driven logging, scripting and datalogging are supported, along with a broad choice of sensors. Our development pipeline includes new control engine options for really difficult control environments.

Those who have used Series 3 or Series 4 will find Series 5 faster, much easier to use, more flexible and more fault tolerant.

Controllers:

BlueBoard Ultra is our top of the range controller suitable for multi controller installations. BlueBoard Mega+ is a very robust controller well suited to most single controller applications. Linear options are available on request.

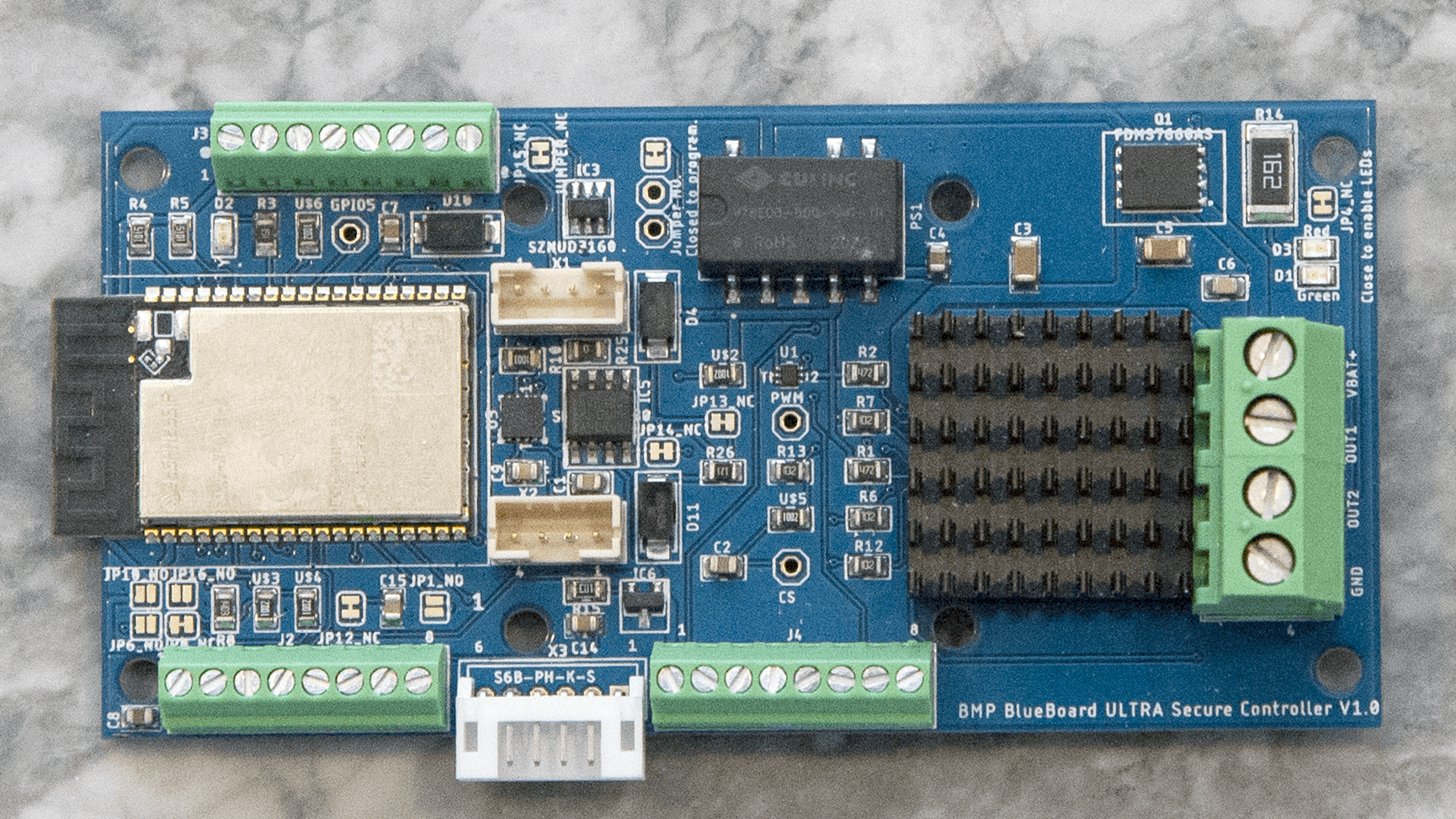

The BlueBoard Ultra Controller is our flagship controller. Multiple Ultra Controllers can collaborate on a CAN Bus style bus to provide very accurate, fault tolerant control to points, areas and volumes. (Details Below)

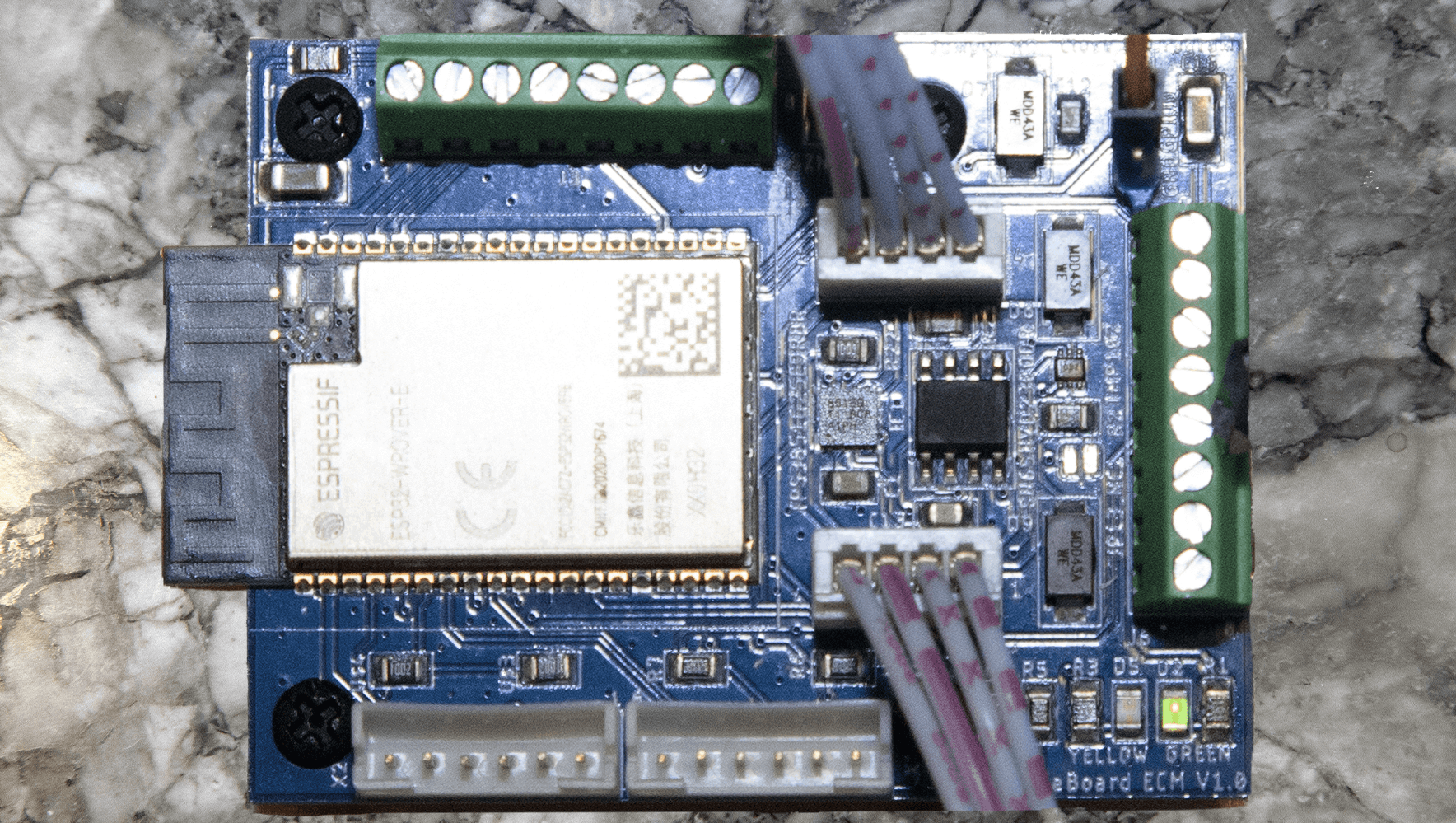

The BlueBoard ECM provides extra capability to any CAN Bus connected BlueBoard Controller. Designed to facilitate quick, reliable development of bespoke control solutions. (Details Below)

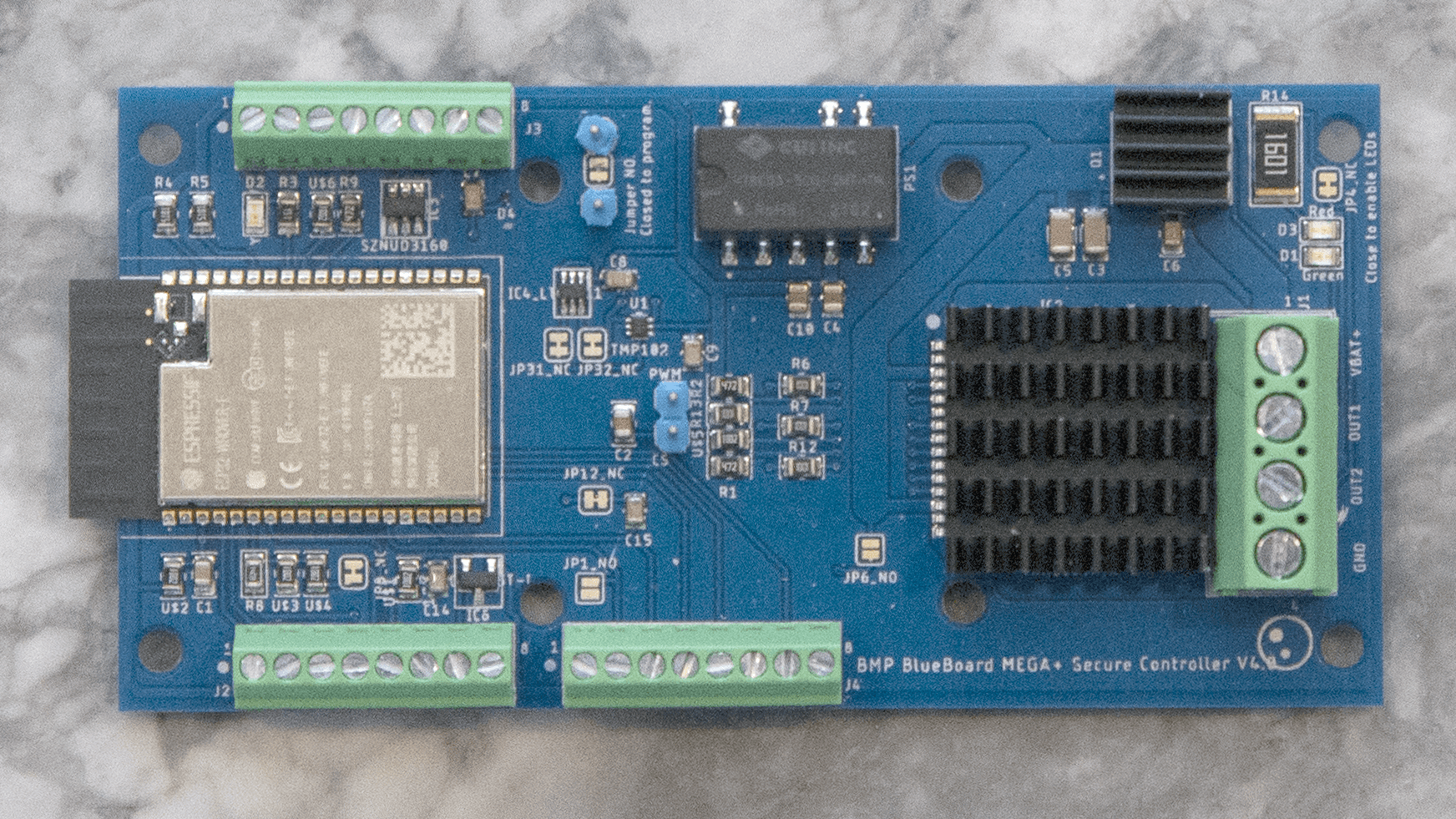

The BlueBoard MEGA+ is an updated version of our workhorse controller, the BlueBoard MEGA. For many applications this controller and a simple NTC sensor are all that are required for high precision temperature control. (Details Below)

The BlueBoard Ultra Preamplifier provides low noise high bandwidth inputs for industry standard thermocouples and PT100 sensors. (Details Below)

All our Series 5 controllers include a datalogger, but for improved performance, we stripped the system down to the bare essentials to make this high speed datalogger. (Details Below)

Advanced Sensors

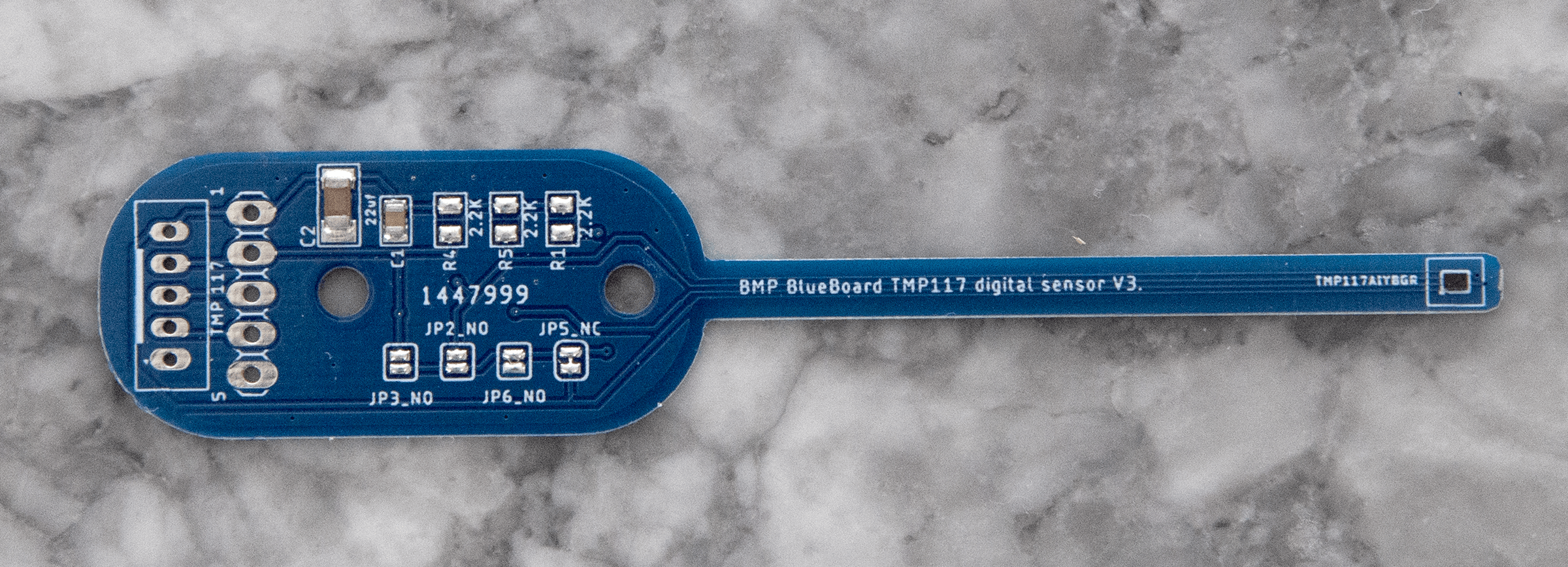

Our "standard" NIST traceable semiconductor sensor. (Details Below)

A NIST traceable semiconductor sensor combined with an interpolating NTC sensor. (Details Below)

A simple 3 NTC sensor with an extended operating range compared to a standard NTC sensor (Details Below)

BlueBoard Controllers

All our controllers work with standard NTC sensors. For many applications this is enough, If you need more you can add the BlueBoard Ultra Preamp and industry standard thermocouples or PT100 sensors. Alternatively you can add one of the NIST traceable semiconductor sensors outlined below. See Our Technology to learn more about our controller technology. (Our original MicroBear Mega controller with Series 4 OS is only available from our Japanese distributor. Please contact us for details. )

BlueBoard Ultra Controller with Series 5 OS

Fault tolerant cooperation with up to 8 other controllers or the ECM and no single point of failure.

Built-in independent hardware supervision.

System error monitoring and fault recovery.

Most recent version of the BMP PID Engine.

Broad support for NTC, PTC, semiconductor and thermocouple sensors.

High speed sensor and data interpolation support.

Most recent version of the system alarm module.

Full web based interface.

Completely new command processor with expanded addressing and response options.

Completely new script engine.

Completely new command driven logging.

ECM and high performance preamplifier support.

Digital load balancing with automatic failover.

“SmartFan” option reduces operating noise.

Multiple datalogging formats.

BlueBoard ECM

Fault tolerant cooperation with up to 8 other ECM units or controllers and no single point of failure.

Built-in independent hardware supervision.

System error monitoring and fault recovery.

Broad support for NTC, PTC, semiconductor and thermocouple sensors.

Support for Series 5 OS, designed for bespoke applications.

BlueBoard MEGA+

System error monitoring and fault recovery.

Most recent version of the BMP PID Engine.

Broad support for NTC and semiconductor sensors.

High speed sensor and data interpolation support.

Most recent version of the system alarm module.

Full web based interface.

Completely new command processor with expanded addressing and response options.

Completely new script engine.

Completely new command driven logging.

“SmartFan” option reduces operating noise.

Multiple datalogging formats.

BlueBoard Datalogger V4+

Designed for use with standard NTC sensors or the BlueBoard 117 semiconductor sensor, the standard configuration of the datalogger can record samples approximately every 100mS. Faster bespoke configurations are possible.

The datalogger works the same way as the datalogger in all Series 5 controllers - only faster!

BlueBoard Advanced Sensors

All our controllers work with standard NTC sensors. For many applications this is enough, If you need more you can add the BlueBoard Ultra Preamp and industry standard thermocouples or PT100 sensors. Alternatively you can add one of the specialty sensors outlined below.

BlueBoard 117 Sensor

Built around the TMP117 this sensor must be protected from extreme electrical and environmental conditions. The BlueBoard 117 Sensor provides NIST tracible temperature recording. Demanding environments require a suitably prepared thermocouple or PT100. (Return to top of page)

BlueBoard Ultra Active Sensor

This probe uses a semiconductor sensor and a standard NTC and must be protected from extreme electrical and environmental conditions. Within the Series 5 OS the NTC is used to interpolate between readings with the slower semiconductor sensor. This process is very useful in certain demanding applications. (Return to top of page)

BlueBoard Extended Range Sensor

The accuracy of standard NTC configurations drops off at high and low temperatures. This is unimportant for many applications where control is targeted at a limited range of temperatures.

The BlueBoard extended range sensor is designed for applications that need a lower cost sensor that is accurate over an extended range (for example cyclical testing) . The sensor uses three differently biased NTC devices. Within the Series 5 OS the reading is derived from the best NTC for the given temperature.

This sensor must be protected from extreme electrical and environmental conditions. Demanding environments require a suitably prepared thermocouple or PT100. (Return to top of page)